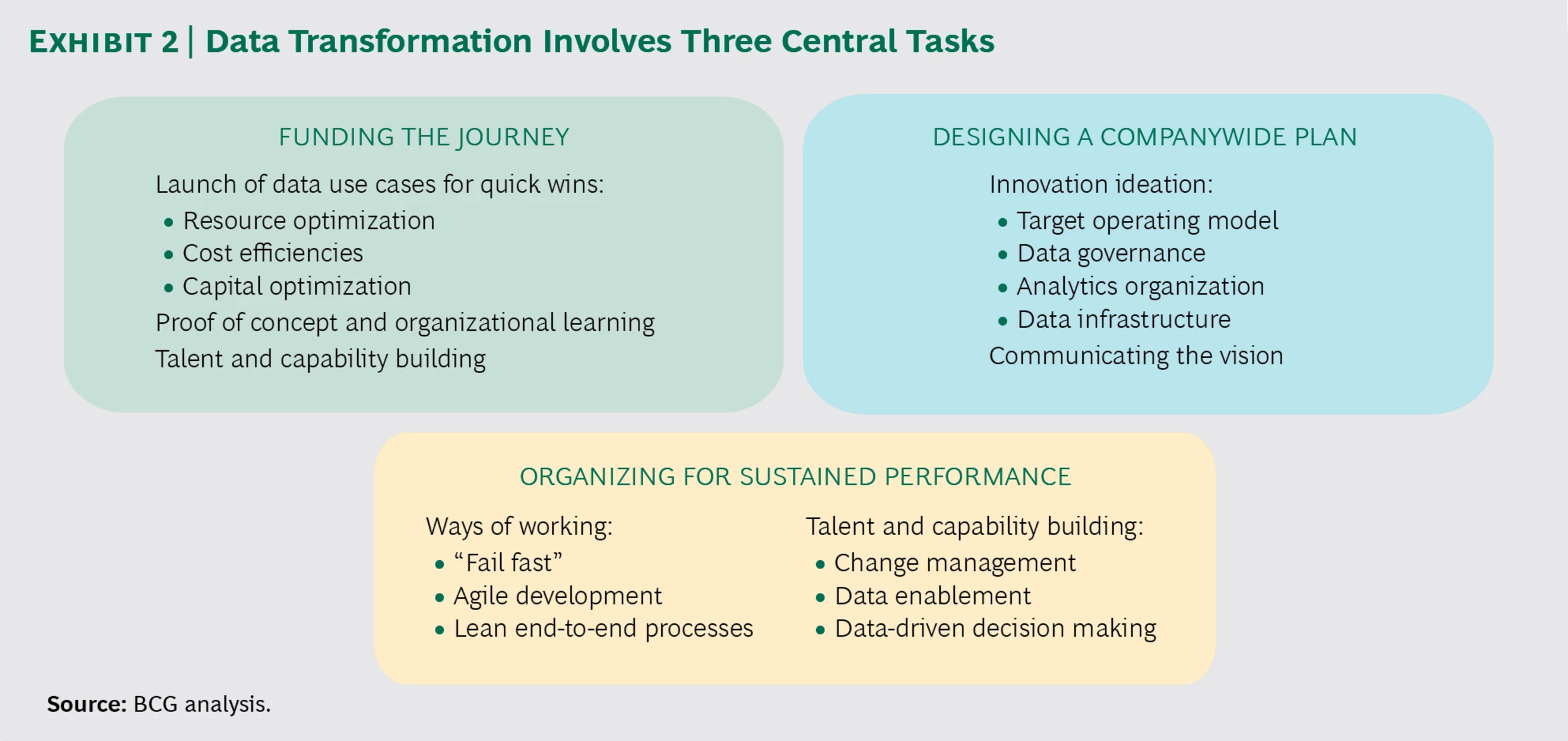

Data-driven transformation has taken to drive change in public and social sectors. Such change has motivated most executives to find reliable ways to propel their companies into data-based futures. Along with motivation, fear to keep up with competitors and ensure survival of their businesses pushes CEOs to implement a focused, pragmatic, and agile approach to data transformation. Working with different industries, BCG has addressed this challenge and developed a cost-effective, sustainable, and progressive three-phase approach:

1. Funding the journey

Entails laying the foundation with rapid digitization efforts that address the basics of broader transformation and deliver returns that can fund later phases. The benefits of these pilot projects help to show how an example company can benefit from digitization in the long run.

2. Designing a company-wide transformation

Focuses on optimizing performance through digitization. In this phase, companies should draw on wins from phase one and create a detailed roadmap for extending transformation to other areas of the enterprise. Additionally, identifying benchmarks to digitize functions and operations allows companies to prepare for a full-fledged digital transformation. In this phase, it is also helpful for the organization to start “industrializing” data analytics—using analytics as a resource for each operation.

3. Organizing for sustained performance

Involves building long-term systems and working towards using new data-driven strategies. As the company continues to sketch its transformation roadmap, it should standardize data-based systems for an effective output. Finally, to ensure sustainability of adopting digital processes, companies should constantly encourage new ways to use data.