Sometimes less is more. In manufacturing, thinking smaller helps your operation be more effective and efficient. That’s where lean manufacturing comes in.

Lean manufacturing best practices focus on how employees and managers collaboratively work and deliver customer value by eliminating waste. Anything that doesn’t add value to the customer and requires an investment of time, money, and talent is considered waste, from inefficient processes and idle time to underutilized talent and excess inventory.

Software-driven manufacturing already streamlines your operations, taking the guesswork out of myriad processes. So is there a way to marry manufacturing software with lean manufacturing best practices to be even more efficient? Of course! Let’s break down a few strategies to put you on the right path.

Go Paperless

Though this is not a new approach, going paperless with automatic tools like the ones from Worximity helps to streamline manufacturing. You might be able to track some things by hand, but manual Excel processes aren’t sustainable because reports completed via manual entry are prone to human error. The right automated technology tools are more reliable and accurate in the long term, helping you eliminate operational issues.

Worximity’s full suite of manufacturing software products makes manufacturing and continuous improvement easier than ever. From data collection to real-time dashboard visibility, get the insights that matter most—anytime.

Tile+

Worximity’s Tile+ manufacturing software collects and correlates real-time production data for improved decision-making. Data is available across devices in user-friendly dashboards that display the exact information you need to act immediately and increase your efficiency. Your entire team can easily see relevant metrics and even respond remotely when needed.

Tilelytics

With Tilelytics, it’s easy to analyze manufacturing patterns and highlight roadblocks. Learn what’s working and what’s not, and isolate the causes of unplanned downtime. This post-production intelligence system provides insights to cut costs and improve production, all while facilitating stronger teamwork and improved decision-making.

Tileconnect

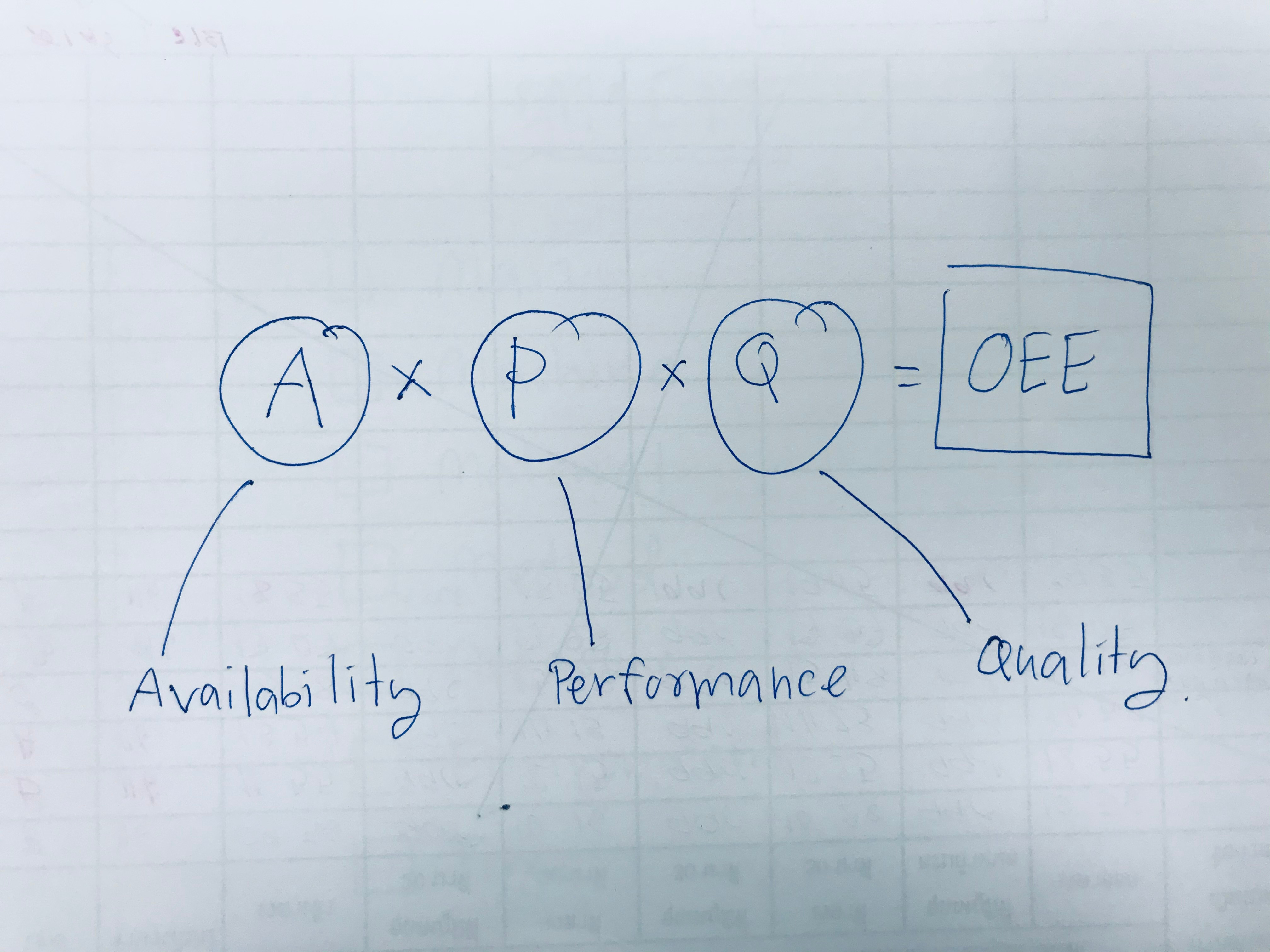

The Tileconnect attachment is the engine that drives both Tile+ and Tilelytics, connecting to your existing equipment to collect production data. Equip your machinery with Tileconnect to measure cycle time, setup time, downtime, production speed, and rejected products. If your factory is doing too much, track your overproduction—or giveaway—in real time to find the best way to adjust.

Adopt a “Pull” Strategy

Software-driven manufacturing can refocus your factory’s attention on customer needs. In doing so, you deploy the “pull” concept of lean manufacturing. That is to say, your factory manufactures particular products only when customers order them, operating with a “just-in-time” mentality.

By adopting a pull strategy, your factory decreases the costs and wastes of mass production, including:

- Inventory carrying costs

- Waste

- Risk

Instead, just about any product can be made to order and delivered to your customers’ hands as quickly as any mass-produced items shipped from a warehouse.

Support High-Mix Low-Volume (HMLV) and Low-Mix High-Volume (LMHV)

Manufacturing changes depending on what your factory is making. Producing a large quantity of identical items (LMHV) or a small quantity of several different items (HMLV) previously required vastly different manufacturing processes.

Software-driven manufacturing enables you to shift your processes depending on the scope of products to be produced, handling LMHV and HMLV runs equally well. As market conditions change, this flexibility makes it easy to rethink what and how to manufacture on the fly.

Consider this: As COVID-19 began to spread, public “lockdowns” started happening all over the world. Pre-pandemic, the supply chain for both consumer and food-service companies was relatively balanced. But once the pandemic hit, people stopped eating in restaurants, making the demand for food-service supplies plummet. Food-service suppliers went from operating under LMHV to immediate HMLV. Manufacturing on demand and with highly analytical software tools makes this flexibility much easier and quicker.

Enhance Your Operations with Worximity’s Manufacturing Software

If you’re struggling to improve your operational efficiency and want to get the most out of lean manufacturing best practices, Worximity has you covered. Our Tile suite products reduce the amount of manual work and data collection required each day to transform your factory into a truly software-driven operation. Benefits of our Tile suite include:

✓Real-time dashboards

✓On-demand reporting

✓Enhanced decision-making

Get actionable insights from top-notch manufacturing software systems. Check out our lean manufacturing E-book, and get in touch with an expert to discuss how Worximity can help you!