While there are many causes of factory rejects, here are five common causes for rejects and wasted parts in manufacturing.

1 - Technical work instructions

Errors in technical work instructions could lead to human error from following false instructions. These errors take a variety of forms, including the following: machines could be misused, parts could be assembled in the wrong order or the wrong way, resulting in damaged components. The solution for this problem would be improving the quality of the work instructions by getting feedback from the employees as they are the ones who must follow the work instructions.

2 - Employee’s level of skill

Training employees on the proper use of equipment and proper handling of components is a very important part of manufacturing. An employee who knows how to do their job properly will not only reduce potential human error, but will also be able to spot potential problems before they arise. Having well trained employees is a major asset when it comes to problem solving and reducing rejects.

3 - Misuse of machines

One “category” of errors that can occur from both poor work instructions and lack of employee training is the improper use of machines. This can happen in the form of misaligned machines, improper calibration, and misuse of tools. These errors can be improved by knowing how to use the machines properly in order to get the best quality product.

4 - Malfunctioning equipment

Malfunctioning equipment occurs when equipment fails suddenly and can be caused by misuse of machines as well as use over time. Every piece of machinery is expected to fail over time, however scheduled maintenance and proper care can prolong the life and reduce problems with the equipment.

5 - Miscellaneous

There are several other causes of rejects, many of which are more task and industry - specific. These “miscellaneous” causes are most often explained by looking at why the part does not meet the standards and then problem solving fix the error.

While most will fall under these 5 broad categories, there are of course more types of reject causes, some of which are more difficult to diagnose. That being said, knowing these main types allows proper planning; improving the time, money, and labor spent on production.

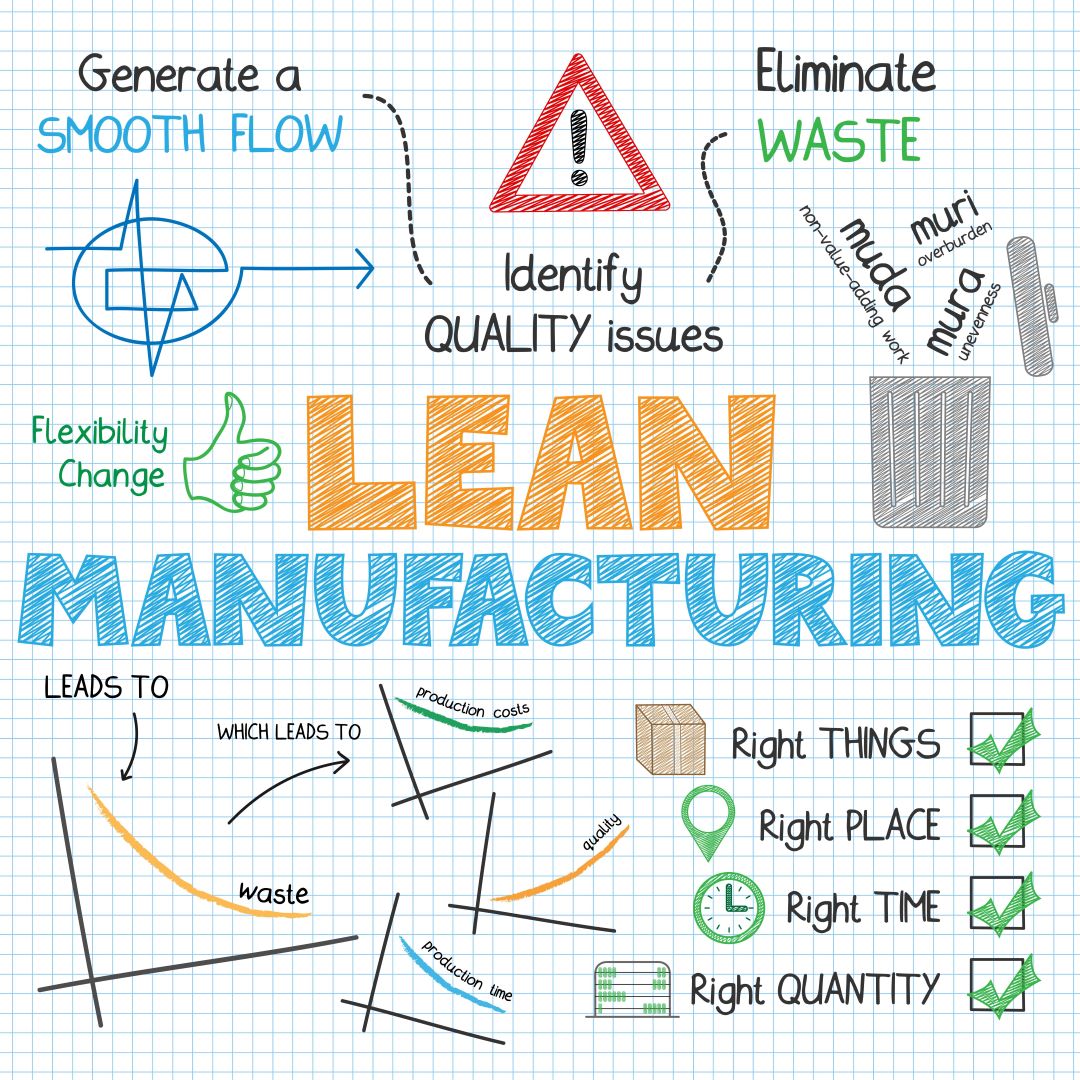

Worximity is deeply committed to the philosophies of Continuous Improvement and Lean Manufacturing in food manufacturing. Using our IoT technology we provide company wide visibility into the statistics that matter to manufacturers and accelerate TTV (Time to Value) of investments in company culture and training to achieve outstanding productivity.