In an article for Matthews Intelligent Identification, Matt Nicol describes the 12 most important manufacturing metrics. The most important of them all? Throughput. Perhaps the simplest of all metrics, Nichol writes that monitoring throughput "measures the average number of units being produced on a machine, line, unit or plant over a specified period of time, e.g.: units per minute."

Why monitoring throughput is the most important of manufacturing metrics?

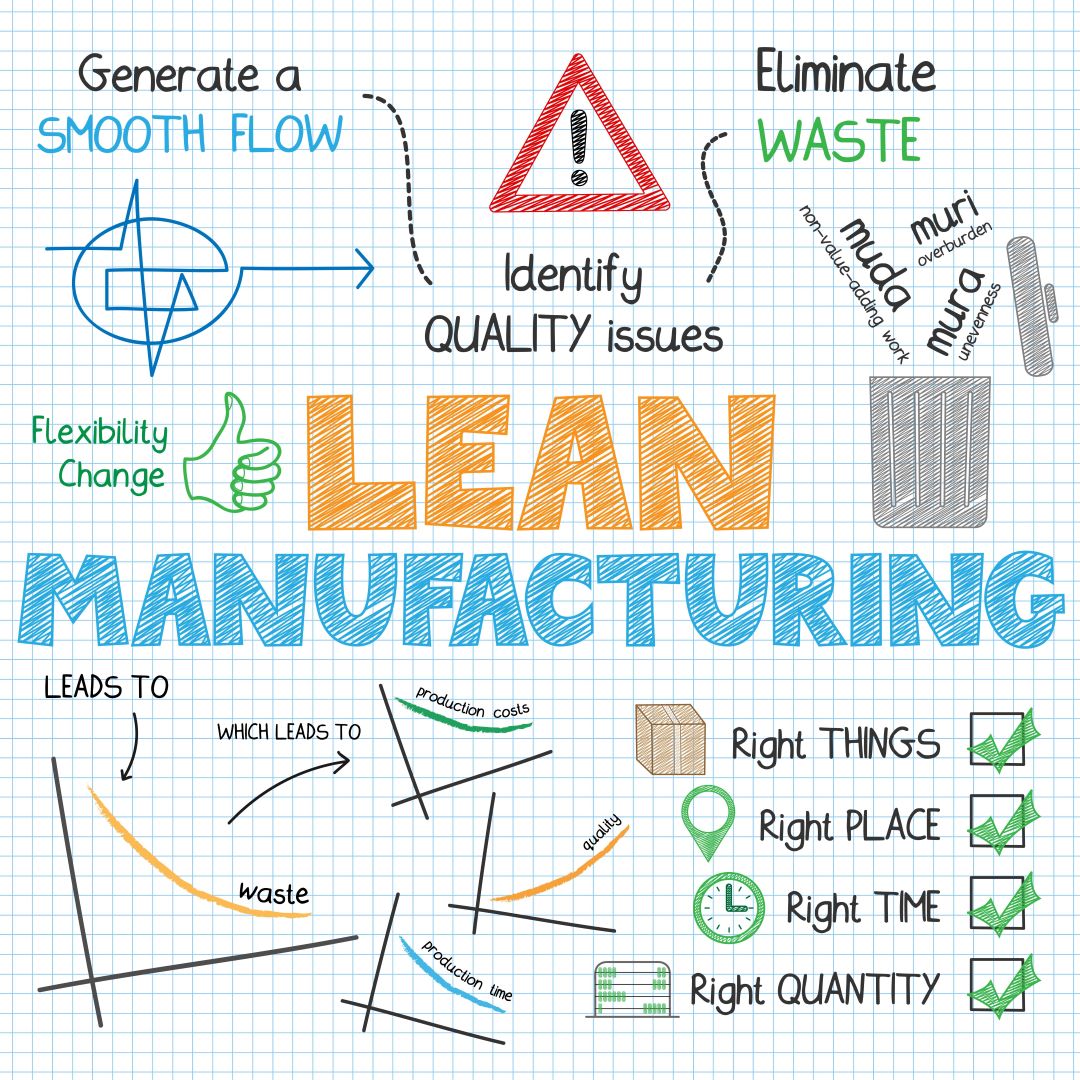

Nichol explains, "If your throughput suddenly decreases, you know that you have an issue on the line. Improving throughput can be achieved with automated equipment, lean processes," and more.

In addition to monitoring throughput, 11 other key important manufacturing metrics are:

Manufacturing cycle time

Time to make changeovers

Capacity utilisation

Overall Equipment Effectiveness (OEE)

Schedule or production attainment

Percentage planned vs emergency maintenance work orders.

Availability

Yield

Customer rejects/returns

Supplier quality incoming

Customer fill rate, on-time delivery, perfect order percentage

Source + read the entire article